-

Metal Fiber Laser Cutting Machine

-

Industrial Laser Cutting Machine

-

Fiber Laser Tube Cutting Machine

-

Laser Cleaning Machine

-

Handheld Laser Welding Machine

-

Fiber Laser Marking Machine

-

UV Laser Marking Machine

-

Laser Welding Machine

-

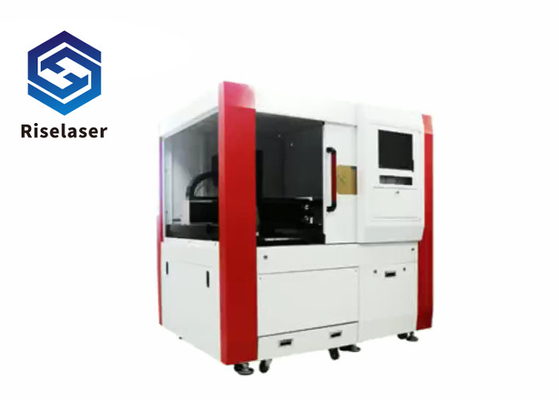

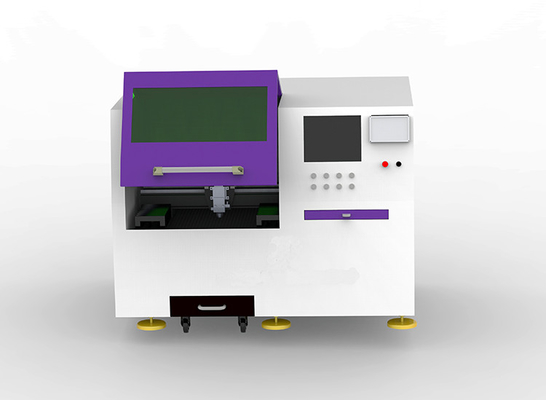

Precision Fiber Laser Cutting Machine

-

Jewelry Laser Welding Machine

-

3D Metal Printing Machine

-

Laser Fume Extraction Systems

-

Fiber Laser Source

-

Laser Machine Parts

-

CO2 Marking Machine

-

Laser Obstacle Remover

-

Gold Testing Machine

-

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine!

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine! -

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service.

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service. -

StefanoThe machine looks sturdy...well built.. like it!

StefanoThe machine looks sturdy...well built.. like it!

500W Precision Fiber Laser Cutting Machine Clean Cut Surface With Water Cooling System

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | High Precision Fiber Laser Cutting Machine For With Small Cutting Area For Metal Cutting | Laser Power | 500W/800W/1000W/2000W/3000W |

|---|---|---|---|

| Working Area | 500*500mm | Max Moving Speed | 60m/min |

| Positioning Accuracy | ± 0.01-0.03 | Powe Supply | 3×380V±10% 220V±10% |

| Package | Wooden Case | Warranty | 1 Year |

| Application | Metal Material | Control Software | Cypcut |

| CNC Or Not | Yes | Condition | New |

| Highlight | fiber cutting machine,small cnc laser cutting machine |

||

500W High Precision Fiber Laser Cutting Machine for with Small Cutting Area for Metal Cutting

Products Description:

1) Fiber laser cutting is the fastest process for thin sheet metal.

2) A “clean cut” surface quality is obtained.

3) Reflective materials like aluminium,copper and brass can be cut with ease.

4) Parts process cost is very low.

5 ) Little to no maintenance costs.

6) Consumable part cost is low. The only parts that need to be changed are nozzles, ceramics and protection glasses over long periods. There are no other consumable costs.

7) Resonator life is over 100,000 working hours.

Main Features of 500W High Precision Fiber Laser Cutting Machine:

| BALL RAIL SYSTEM | |

|

Smooth & friction guided motion, high precision & high speed ball, long life & better load carrying capacity.

|

|

|

BALL SCREW MECHANISM

|

|

|

Precision movement imparted through ball screw mechanism. Supreme quality of ball screw to provide high accuracy and repeatability at high speed with low noise runner block.

|

|

|

USER FRIENDLY SOFTWARE

|

|

|

User-friendly software for laser power and pulse frequency, pulse duration along with position control.

|

|

|

NESTING

|

|

|

Nesting software to nest different types of jobs in single sheet and optimal use of raw material. Accommodation of different types of jobs from scrap material & common edge cutting. Complete material management through user-friendly software.

|

|

|

HEIGHT SENSING UNIT |

|

|

Adjusting preset height automatically. It helps to cut little sloppy (non-flat or non-linear) surface of sheet. Non-contact & contact types of versions are available.

|

|

|

STRUCTURAL DESIGN

|

|

|

Structural design is such that it can withstand heavy loads. Vibration pads are used for sustaining the structural damping.

|

|

| REMOTE CONTROL | |

| Flexible machine controls from remote place with emergency stop facility, easy to understand or self-explanatory audio & video display machine. | |

| SHEET LOADING & CLAMPING | |

| Pneumatically actuated loader with ball on the top of it for easy sliding of the sheet. Pneumatically controlled firm clamping on the sheet. It can adjust the position of the clamp on the table. Safe loading and clamping for operator who is loading and un-loading the sheet. | |

| DETACHABLE OPTICS | |

| Replacements of mirror without any change in linked alignments. | |

| THERMAL OPTICS STABILITY | |

| Parallel water-cooling system with temperature control. It eliminates the thermal expansion of optics and increases peak power life. | |

| OPTICS BELLOWS | |

| Metallic bellows for protection of optics form contamination. | |

| CONTROL & DISPLAY | |

| SIEMENS or PC based SLT Ltd. controls available. |

Advantages of 500W High Precision Fiber Laser Cutting Machine:

|

|

Fiber Laser Generator

|

YAG Lamp Pump Laser Generator

|

CO2 RF Metal Laser Tube

|

|

Power

|

500W/750W/1000W/2000W/3000W

|

500W/650W/850W

|

300W/500W

|

|

Advantages

|

Excellent laser beam quality, high cutting precision, high cutting speed, high efficient photoelectric conversion rate, low use-cost and maintenance cost, easy operation and convenient maintenance

|

Compared with fiber laser generator and CO2 RF metal laser tube of the same power, it has lower price, thicker material cutting ability, wider application field and lower one-time investment.

|

It can cut metal sheets and non-metal materials. Wider range of applicable materials. Adjustable output power. Maintenance free. Easy to operate and convenient to use.

|

|

Applicable Materials

|

All kinds of metal sheets and pipes

|

All kinds of metal sheets and pipes

|

All kinds of metal sheets and other nonmetal materials

|

|

Applicable Industry

|

Sheet metal, hardware, watches, metal art craft works, etc.

|

Sheet metal, kitchenware, metal letters and accessories & hardware, etc.

|

Sheet metal, advertising, furniture and

|

Technical Parameter:

| Model | RL5050 | |

| Working size | 500×500(mm) | |

| Max. Acceleration | 1.2g | |

|

X AXIS |

Max. Moving speed | 60m/min |

| Route | 500mm | |

| Positioning accuracy | ±0.01mm | |

| Repeatition accuracy | ±0.004mm | |

|

Y AXIS |

Max. Moving speed | 60m/min |

| Route | 500mm | |

| Positioning accuracy | ±0.01mm | |

| Repeatition accuracy | ±0.004mm | |

| Z AXIS | Route | 100mm |

3. Working condition

| 1 | Working temperature | -10℃~45℃ |

| 2 | Relativede Humidity | <90% no condenser |

| 3 |

Environment |

Good ventilation, no vibration |

| 4 | Power supply | 3×380V±10% 220V±10% |

| 5 | Power frequency |

50Hz |

| Item | Parameter |

| collimation | 100mm |

| focus | 125mm |

| optical aperture | 25mm |

| nozzel (single) | :0.8/1.0/1.5/2.0/2.5/3.0/3.5/4.0mm |

| lens materials | quartz |

| fiber plug | QBH |

| Auxiliary pressure | Max. 20bar |

| weight |

~1.5Kg |

Application of Precision Fiber Laser Cutting Machine:

Suitable for carbon steel ,mild steel,SS ,aluminum alloy plate and copper plate and other metal.It is suitable for medium and thin thickness material processing.

Applied in sheet metal processing, aviation, aerospace, electronics, electrical appliances, tube fittings, automobile, food machinery, textile machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, sheet metal processing, kitchen utensils and appliances, craft gifts, tool processing, decoration, advertising, metal processing and other manufacturing industries.

Cutting Parameter:

| Power(W) | Material | Thickness(mm) | Cutting speed(m/min) | Gas |

| 800 | Stainless steel | 1 | 8-9 | N2 |

| 2 | 5-6 | N2 | ||

| 3 | 1.8-2 | N2 | ||

| 4 | 1.2-1.3 | N2 | ||

| 800 | Carbon steel | 1 | 8-10 | O2 |

| 2 | 4-5 | O2 | ||

| 3 | 2.8-3 | O2 | ||

| 4 | 1.4-1.8 | O2 | ||

| 5 | 1.2-1.5 | O2 | ||

| 6 | 0.9-1.1 | O2 | ||

| 8 | 0.6-0.7 | O2 |