-

Metal Fiber Laser Cutting Machine

-

Industrial Laser Cutting Machine

-

Fiber Laser Tube Cutting Machine

-

Laser Cleaning Machine

-

Handheld Laser Welding Machine

-

Fiber Laser Marking Machine

-

UV Laser Marking Machine

-

Laser Welding Machine

-

Precision Fiber Laser Cutting Machine

-

Jewelry Laser Welding Machine

-

3D Metal Printing Machine

-

Laser Fume Extraction Systems

-

Fiber Laser Source

-

Laser Machine Parts

-

CO2 Marking Machine

-

Laser Obstacle Remover

-

Gold Testing Machine

-

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine!

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine! -

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service.

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service. -

StefanoThe machine looks sturdy...well built.. like it!

StefanoThe machine looks sturdy...well built.. like it!

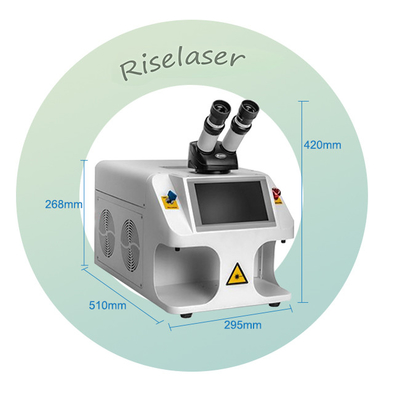

Mini 60w Jewelry Laser Welding Machine Build In Water Air Cooling

| Machine Model | Jewelry Laser Welding Machine | Key Word | Jewelry Welding Machine |

|---|---|---|---|

| Laser Power | 40W 60W 80W 100W 200W | Observation System | 10X Microscope + HD CCD |

| Cooling System Dimensions | Build-In Water Cooling + Air Cooling | Pulse Energy | 40J/60J/90J |

| Peak Pulse Power | 3.5kw/7.5kw | Machine Size | L51CM×W29.5CM×H42CM |

| Power Supply | 220VAC 10% / 50-60HZ | Application | Jewelry, Watch, Glasses, Dental Welding |

| Highlight | 60w Jewelry Laser Welding Machine,3.5kw Jewelry Laser Welding Machine,60w Mini Laser Welding Machine |

||

Mini 60w Jewelry Laser Welding Machine Build In Water Air Cooling

Mini 60w jewelry laser welding machine air cooling jewelry welding machine

Machine Feature:

1. It can realize spot welding, butt welding, seam welding and sealing welding. The advantage is high positioning accuracy and easy robotization

2. The working space is large, convenient to place various tools and clean up welding shavings

3. The jewelry laser welding machine adopts YAG technology, so the xenon brand and crystal rod are the core parts of the whole laser welding machine

4. Contains a ring-shaped shadowless adjustable brightness LED light, which makes the welding area clearer and meets the requirements of fine welding

5. Built-in high-definition CCD can make the operation easier

6. The high-quality 10x magnification microscope is favored by professionals

![]()

Machine dimension of 60w

![]()

What material the small jewelry laser welding machine works?

This welding application is great for precious metals, which is why most jewelers in Australia use jewelry laser welding machines.

All traditional jewelry metals can be laser welded:

all base metals

Krakin

Sterling silver

titanium

palladium

platinum

Platinum is one of the most difficult metals in history to machine and repair, and one of the easiest to laser weld. It is also possible to weld dissimilar metals together, such as gold to platinum and sterling silver to gold.

Operating system supported languages: Chinese, Turkish, Arabic, English, Korean

1. Observation system: The observation system of this jewelry spot welding machine consists of a microscope and a built-in high-definition CCD camera. Users can choose one or both of them as the observation method according to their needs. Both can clearly observe the welding position of the workpiece, which is convenient for welding.

2. Adjustment of the CCD cross cursor: If the light spot is not in the center of the cross cursor in a very clear position of the CCD camera system, you can change the position of the cross cursor by clicking the middle position of the four cross cursors. the sides of the screen so that the solder joint is in the center of the cursor

3. For welding operations, first ensure that the machine has been turned on normally, put the workpiece into the sight of the observation system, and then slowly move to the clearest position of the observation system.

Point the cursor to the desired welding position, gently step on the foot switch, the machine has laser output for welding.

4. Parameter adjustment, focusing, after the first welding, the welding effect of the solder joint does not meet the requirements, and the parameters need to be adjusted again. Focusing (-3.0-+3.0) makes the welding effect meet the requirements, and will not repeat the welding in the future. Needs to be readjusted.

Specification

| Size(mm) | L51CM×W29.5CM×H42CM |

| Net weight | 28KG |

| Total power | 2KW |

| Rated power | 60W |

| Laser frequency | 1.0~15.0HZ continuously adjustable |

| Pulse Width | 0.1~10.0MS grade adjustable |

| Aiming and positioning | Built-in camera system 7-inch screen and microscope |

| Light spot | 0.15~2.0mm |

| Water injection | Automatic pumping |

| cooling method | Water cooling |

Welding Samples

![]()

Video

Application Scope

Our machines are widely used in jewelry industry, hardware industry, tool industry, instrumentation industry, automobile industry, energy industry, building material industry, model and machinery manufacturing, electronic and electrical industry. For more details, please contact us.