-

Metal Fiber Laser Cutting Machine

-

Industrial Laser Cutting Machine

-

Fiber Laser Tube Cutting Machine

-

Laser Cleaning Machine

-

Handheld Laser Welding Machine

-

Fiber Laser Marking Machine

-

UV Laser Marking Machine

-

Laser Welding Machine

-

Precision Fiber Laser Cutting Machine

-

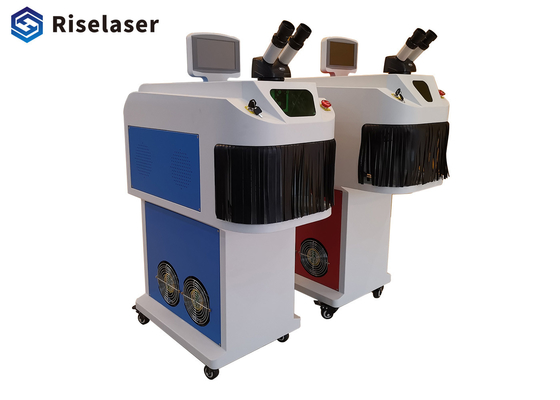

Jewelry Laser Welding Machine

-

3D Metal Printing Machine

-

Laser Fume Extraction Systems

-

Fiber Laser Source

-

Laser Machine Parts

-

CO2 Marking Machine

-

Laser Obstacle Remover

-

Gold Testing Machine

-

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine!

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine! -

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service.

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service. -

StefanoThe machine looks sturdy...well built.. like it!

StefanoThe machine looks sturdy...well built.. like it!

CCD 200w Jewelry Laser Soldering Machine With 10 Times Microscope

| Laser Source | Jewellery Laser Welding Machine | Water Tank Capacity | 13L (Distilled Water Or Pure Water) |

|---|---|---|---|

| Operating Mode | Touch Control | Pump Source | Single Lamp |

| Aiming And Positioning | Microscope + CCD Camera System | Cooling System | Build In Water Recycling |

| Laser Beam Diameter | 0.15~2.0 Mm | Machine Adjustable Beam Diameter | ±3.0 Mm |

| Highlight | 200w Jewelry Laser Soldering Machine,CCD Jewelry Laser Soldering Machine,200w laser jewellery welding machine |

||

CCD 200w Jewelry Laser Soldering Machine With 10 Times Microscope

Product Description

1. Imported ceramic condenser cavity, high reflectivity, strong energy, high temperature resistance, corrosion resistance and long service life;

2. The whole machine conforms to the ergonomic design, which is more suitable for the jewelry industry. The product is exquisite, beautiful, and has stable performance, which is suitable for long-term continuous work;

3. Large internal space, convenient to place laser spot welding fixtures; Install welding slag recovery box to facilitate cleaning and gold welding slag recovery;

4. LED ring shadowless lamp, observing the workpiece without shadow, with the high-definition parallel light path microscope, the laser welding position can be observed more clearly;

5. High-power beam expansion system to obtain a more precise spot to meet the needs of fine laser spot welding.

6. upport languages: Chinese, Turkish, Arabic, English, Korean

![]()

Specification of jewelry laser welding machine for gold

| Laser System | RL-Y200 MINI |

| Laser Type | 1064nm YAG Laser |

| Nominal Laser Power | 200W |

| Laser Beam Diameter | 0.15~2.0 mm |

| Machine Adjustable Beam Diameter | ±3.0 mm |

| Pulse Width | 0.1-20 ms |

| Frequency | 1.0~50.0Hz Continuously Adjustable |

| Maximum Laser Pulse Energy | 80J |

| Host Power Consumption | ≤6KW |

| Cooling System | Build in Water Recycling |

| Water Tank Capacity | 13L (Distilled Water) |

| Aiming and Positioning | Microscope + CCD Camera System |

| Operating Mode | Touch Control |

| Pump Source | Single lamp |

| Display Touch Screen Mounting Dimensions | Mounting Dimension: 200*135mm Touch Screen dimension: 7" (16:9) ,Size: 155*87(mm) |

| Operating Language | English, Turkish, Korean, Arabic |

| Electrical Connection Values | AC 220V ± 5%, 50HZ / 60HZ |

| Machine Dimension | L70CM×W35CM×H96CM |

| Wooden Package Dimension | L88CM*W48CM*H125CM |

| Machine Net Weight | N.W.:92KG; |

| Machine Gross Weight | G.W.:99KG; |

| Operating Environmental Temperature | ≤45℃ |

| Humidity | < 90% non-condensing |

| Application | Welding and repairing all kinds of jewelry and accessories |

Scope of application

Widely used in various metal materials: gold, silver, platinum, copper, stainless steel and other metal materials. Including: rings, earrings, bracelets, necklaces, tie clips, cuffs and other accessories, metal jewelry filling holes, spot welding trachoma, patches, inlays and laser welding claws

![]()

Jewellery laser welding machine main feature

1) One-key operation: One-key switching, which simplifies the startup process and facilitates the use of cumbersome processes.

2) Single-chip microcomputer control and adjustment: 50 sets of commonly used welding machine parameters are stored, which is convenient for reuse.

3) Energy, pulse width, frequency, and spot size can be adjusted in a wide range to achieve different welding effects. The parameters are adjusted by the lever in the sealed cavity, which is simple and efficient.

4) The most advanced shading system is adopted to eliminate the irritation of light to the eyes during work.

5) Ability to work continuously for 24 hours; stable performance; maintenance-free for 10,000 hours.

6) Humanized design, accord with ergonomics, avoid long-time work fatigue.