-

Metal Fiber Laser Cutting Machine

-

Industrial Laser Cutting Machine

-

Fiber Laser Tube Cutting Machine

-

Laser Cleaning Machine

-

Handheld Laser Welding Machine

-

Fiber Laser Marking Machine

-

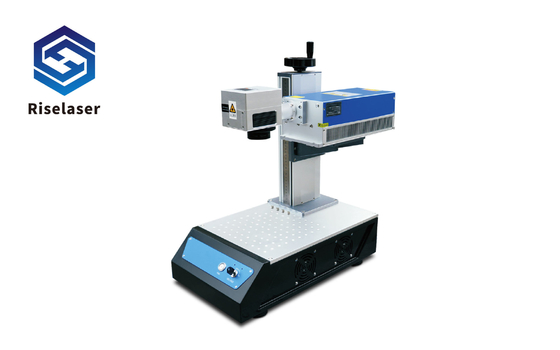

UV Laser Marking Machine

-

Laser Welding Machine

-

Precision Fiber Laser Cutting Machine

-

Jewelry Laser Welding Machine

-

3D Metal Printing Machine

-

Laser Fume Extraction Systems

-

Fiber Laser Source

-

Laser Machine Parts

-

CO2 Marking Machine

-

Laser Obstacle Remover

-

Gold Testing Machine

-

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine!

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine! -

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service.

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service. -

StefanoThe machine looks sturdy...well built.. like it!

StefanoThe machine looks sturdy...well built.. like it!

EZCAD Control 355nm 3W Tabletop Laser Engraving Machine with No Consumbles

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | 3W UV Laser Marking Machine | Working Accuracy | 0.01mm |

|---|---|---|---|

| Control Software | EZCAD | Warranty | 1 Year |

| Laser Wavelength | 355nm | Marking Speed | 0-7000mm/s |

| Certificate | CE | Color | Silver,Blue |

| Highlight | 3W Tabletop Laser Engraving Machine,355nm Tabletop Laser Engraving Machine,EZCAD Control Uv Laser Machine |

||

Product Features

1.All-in-one design

2.Remote computer control

3.External TTL and PWM control

4.Adjustable repetition frequency 20-200kHz

Product Parameter

| RL-UV3 | RL-UV5 | |

| Wavelength | 355nm | 355nm |

| Output power | >3W@30KHz | >5W@40KHz |

| Maximum pulse energy | 0.1mJ@30KHz | 0.12mJ@40KHz |

| Pulse Repetition Frequency | 1-150KHz | 1-150KHz |

| Pulse duration | <15ns@30KHz | <18ns@40KHz |

| Average power stability | <3% | <3% |

| Spatial mode | TEM00 (M²< 1.5) | TEM00 (M²< 1.5) |

| Polarization ratio | >100:1 Horizontal | >100:1 Horizontal |

| 1/e2 beam diameter at output | 0.7mm | 0.8mm |

| Beam circularity | >90% | >90% |

Advantages

1. Cold processing marking: no thermal effect and material burning problem.

2. Strong mechanical stability

3. Strong resistance to external temperature interference

4. Good beam quality

5. High long-term work stability

![]()

![]()

![]()

Applications

1. Laser Marking

2. Micro hole machining

3. Ceramic cutting

4. Thin film etching

5. Wafer cutting

![]()

Packaging & Shipping

![]()

FAQ

Q1. How to get the most suitable machine and the best price?

Please tell us what material you are dealing with and what is the maximum size of the material? We will recommend the most suitable model for you and provide the best price.

Q2. What if we don’t know how to use the machine?

We will send you manuals and guide videos in English, which can teach you how to operate the machine. If you still can't learn how to use it, we are willing to provide online help, for example, we can talk via phone, email or Whatsapp.

Q3. Do you arrange the shipment of the machine?

Yes, dear customers, we will arrange FOB or CIF prices for you.