-

Metal Fiber Laser Cutting Machine

-

Industrial Laser Cutting Machine

-

Fiber Laser Tube Cutting Machine

-

Laser Cleaning Machine

-

Handheld Laser Welding Machine

-

Fiber Laser Marking Machine

-

UV Laser Marking Machine

-

Laser Welding Machine

-

Precision Fiber Laser Cutting Machine

-

Jewelry Laser Welding Machine

-

3D Metal Printing Machine

-

Laser Fume Extraction Systems

-

Fiber Laser Source

-

Laser Machine Parts

-

CO2 Marking Machine

-

Laser Obstacle Remover

-

Gold Testing Machine

-

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine!

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine! -

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service.

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service. -

StefanoThe machine looks sturdy...well built.. like it!

StefanoThe machine looks sturdy...well built.. like it!

Smoke Absorber Laser Cutter Fume Extractor For Laser Cutting / Soldering Machine

| Product Name | Smoke Absorber For Laser Cutting Machine And Soldering Machine | Brand Name | Riselaser |

|---|---|---|---|

| Place Of Origin | China | Certification | CE |

| Warranty | 1 Year | Dimensions | 450*290*450 MM |

| Inlet Diameter (mm) | 50/75 | Noise DB(A) | 65±2 |

| Highlight | laser cutter fume extractor,welding fume extraction system |

||

Smoke Absorber for Laser Cutting Machine and Soldering Machine

RL-HTC series of products features beautiful, safe and quiet purifier specially designed for a large number of fine dust. Equipped with brushless electric motor, it can realize stepless speed regulation. It is also equipped with filter barrel filter + activated carbon double-stage filter.Widely used in laser marking/engraving of metal work pieces, glass, ceramics, stone, etc.

Advantage

-

The filter cylinder type filter, the surface filtration characteristic, does not hold the dust rate limit, the service life is long, generally in 12 months above

-

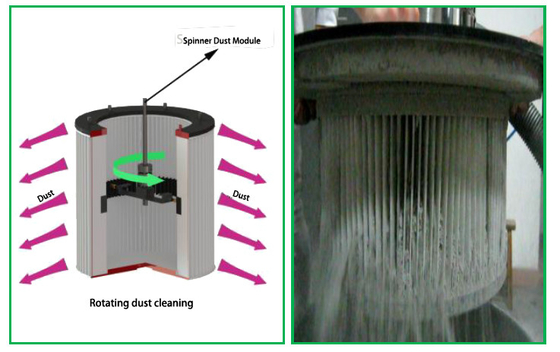

Standard equipped with electric filter shaker device, automatically clean the dust adhering to the filter surface, to avoid filter blockage

-

High quality brushless fan, large air volume, strong suction

-

By manually adjusting the knob, the motor can be stepless speed regulation to increase or decrease the negative pressure and air volume

-

Filter modular structure, easy and quick replacement

-

Universal moving castor design, easy to move

-

SPCC plate with a thickness of 2.0mm, with sufficient material, running smoothly and with little vibration

-

The suction port is at the side of the device, and the air outlet is above the back of the device

-

Standard side connection to client via hose

Technical parameter

|

Model |

RL-HTC350 |

RL-HTC500 |

|

Power (W) |

350 |

500 |

|

Power Supply (V/Hz) |

220/50 |

220/50 |

|

Maximum Flow (m3/h) |

420 | 500 |

| Noise dB (A) | 70±2 | 72±2 |

| Suction Diameter | 50/75 | 50/75 |

| Dimension (mm) | 515*415*860 | 515*415*860 |

| Weight (kg) | 76 | 85 |

![]()

Characteristics

-

No brush fan, low noise running

![]() In terms of power system, single-phase brushless motor is adopted with strong suction, and the 220V power supply can be conveniently connected, and stepless speed regulation can be realized to select air quantity according to the working condition.

In terms of power system, single-phase brushless motor is adopted with strong suction, and the 220V power supply can be conveniently connected, and stepless speed regulation can be realized to select air quantity according to the working condition.

One of the biggest advantages of brushless fan is low noise operation, smooth operation and low noise.Through our special design, the air pressure and air volume parameters are kept at a high level, and the maximum negative pressure can reach 10kpa.

-

Control circuit, safe and reliable

![]()

The electrical system adopts the advanced modular circuit board specially designed by our company to realize PWM stepless speed regulation function.Key components adopt imported brands and materials to fully guarantee the safety and reliability of operation.

In addition, there will be an audible alarm when the filter is detected to be blocked.Remind the user to clean the dust or change the filter.

- Filter cartridge filtration, fine dust first choice

![]()

The filter system adopts high efficiency filter cartridge, the filter cartridge adopts imported base material, PTFE/ anti-static film covering treatment, the filter can be cleaned and reused, greatly reducing the use of consumables.It is the first choice for laser processing metal dust, and solves the problem of easy blockage of plate and frame filter.

- High efficiency of electric dust cleaning and ash cleaning (optional configuration)

![]() The dust removal system adopts optional electric dust removal device.

The dust removal system adopts optional electric dust removal device.

The HTC series purifier has a standard filter surface dedusting structure with electric paddles. The operator only needs to press the dedusting button, and the built-in dedusting motor will automatically run to remove the dust.

Typical Applications

![]()