-

Metal Fiber Laser Cutting Machine

-

Industrial Laser Cutting Machine

-

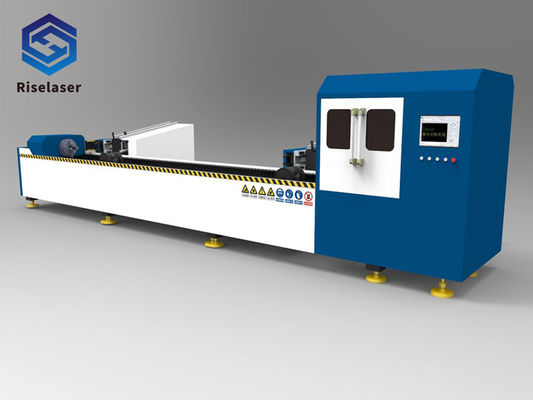

Fiber Laser Tube Cutting Machine

-

Laser Cleaning Machine

-

Handheld Laser Welding Machine

-

Fiber Laser Marking Machine

-

UV Laser Marking Machine

-

Laser Welding Machine

-

Precision Fiber Laser Cutting Machine

-

Jewelry Laser Welding Machine

-

3D Metal Printing Machine

-

Laser Fume Extraction Systems

-

Fiber Laser Source

-

Laser Machine Parts

-

CO2 Marking Machine

-

Laser Obstacle Remover

-

Gold Testing Machine

-

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine!

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine! -

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service.

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service. -

StefanoThe machine looks sturdy...well built.. like it!

StefanoThe machine looks sturdy...well built.. like it!

Fiber Laser Tube Cutting Machine High Cutting Speed For Industry Processing

| Product Name | 3015 Dual-drive Metal Pipes And Plates Fiber Laser Cutter For Industry Processing | Laser Type | Fiber Laser |

|---|---|---|---|

| Laser Power | 500w/800w/1000w | Cutting Area | 3000mm*1500mm |

| Cutting Head | Raytools | Chiller | S&A |

| Highlight | cnc laser tube cutting machine,fiber laser pipe cutting machine |

||

3015 Dual-drive Metal Pipes and Plates Fiber laser Cutter for Industry Processing

Main Features:

Professionally cutting metal sheet 0.5-20mm carbon steel, 0.5-12mm stainless steel, 0.5-10mm brass, 0.5-6mm copper, square pipes, round pipes, rectangle pipes, D-shaped pipes and hexagon pipes etc. Cutting capacity - square pipes:20*20-230*230mm, round pipes diameter: 20-325mm, thickness 0.5-5mm carbon steel pipes, 0.5-3mm stainless steel pipes.

Professionally cutting 0.5-12mm carbon steel, 0.5-6mm stainless steel,0.5-3mm brass, 0.5-2mm copper, as well as galvanized steel, electrolytic steel and silicon steel etc (thicknesses are related to the kinds of materials and fiber source power)D

Advantage of Fiber laser cutting machine:

1. Excellent path quality: Smaller laser dot and high work efficiency, high quality.

2. High cutting speed: cutting speed is 2-3 times than same power CO2 laser cutting machine.

3. Increasing perforation focus length, separately setting perforation focal length and cutting focal length, enhance cutting accuracy.

4. Built-in double water-cooling structures can ensure constant temperature of collimating and focusing components, avoid lenses overheating and extend service life of lenses.

Increasing collimation protective lens and focus protective lens, carefully protect key components.

5. Low cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

6. Low maintenance: fiber line transmission no need reflect lens, save maintenance cost;

7. Easy operations: fiber line transmission, no adjustment of optical path.

High Precision

Satisfy Customer's claims to work the round pipe, square pipe and specially shaped metal.

It is the best choice for the professional production of pipe.

Technical Parameters:

| Model | RL-T500 |

| Laser Working Meduim | Fiber Laser Module |

| MaxOutput Power | 500w/800w/1000w/1500w/2000w |

| Pulse Width | 0.3~20m |

| Pulse Frequency | 1~300Hz |

| Laser Power Stability | ≤±3% |

| Pipe Wall Cutting Thickness | 6000mm |

| Work Table Axis Position Accurancy | ≤±0.08mm/1000mm |

| Work Table Re-orientation Accurancy | ≤±0.04mm |

| Electrical Source | 380V/50Hz/100A |

| Cutting Gas Requirement | Oxygen/ Nitrogen/ Air Mixed Gas |

| Cutting Gas Pressure | >5KG |

![]()