-

Metal Fiber Laser Cutting Machine

-

Industrial Laser Cutting Machine

-

Fiber Laser Tube Cutting Machine

-

Laser Cleaning Machine

-

Handheld Laser Welding Machine

-

Fiber Laser Marking Machine

-

UV Laser Marking Machine

-

Laser Welding Machine

-

Precision Fiber Laser Cutting Machine

-

Jewelry Laser Welding Machine

-

3D Metal Printing Machine

-

Laser Fume Extraction Systems

-

Fiber Laser Source

-

Laser Machine Parts

-

CO2 Marking Machine

-

Laser Obstacle Remover

-

Gold Testing Machine

-

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine!

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine! -

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service.

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service. -

StefanoThe machine looks sturdy...well built.. like it!

StefanoThe machine looks sturdy...well built.. like it!

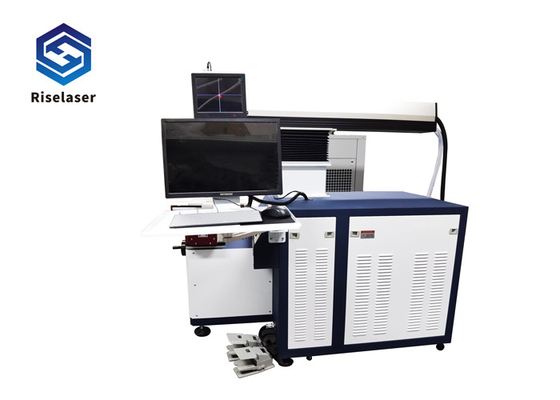

ND YAG Auto 5kW 1064nm Laser Welding Machine For Mould Repair

| Output Power | 300W | Power Consumption | 5kW |

|---|---|---|---|

| Laser Source Brand | MAX | Wavelength | 1064nm |

| Cooling System | Water Cooling | Warranty | 1 Year |

| Weight | 540kg | Equipment Size | 1500x750x1200 Mm |

| Highlight | 1064nm Laser Welding Machine,5kW Laser Welding Machine,ND YAG Laser Welder |

||

ND YAG Auto 5kW 1064nm Laser Welding Machine For Mould Repair

Product Details

The welding machine is specially designed for the mold industry, mainly used to repair precision molds, such as digital products, mobile phones, toys, automotive and motorcycle molds. By using suitable solder wires, cracks or pores can be filled and the mold can be reused, thereby saving production costs and significantly improving work efficiency. It can also be used for tailor welding of thin metal plates, tube-to-tube welding, manufacturing sensors, liquid level switches and fine automotive parts.

Video

Features

1. High-quality ceramic convergent cavity: corrosion resistance, high temperature resistance, and a service life of 8-10 years. The life of the xenon lamp exceeds 8 million flashes.

2. The laser head can rotate 360°, can automatically move up and down, four-axis linkage

3. The parameter modification interface is simple and convenient to operate

4. The size of the light spot can be adjusted automatically accordingly.

5. High-definition CCD for clear imaging of samples

Applicable industry:

1. Widely used in aerospace, machinery, electronics, communications, power, chemical, automobile manufacturing and other industries.

2. Welding of auto parts, such as hydraulic jib, gasoline cleaner, left air sensor, solenoid valve and drive start stator.

3. Tightly weld lithium-ion batteries, such as mobile phone batteries and power batteries.

4. In the metallurgical industry, such as the welding of silicon steel plates.

5. Welding of engines and engine blades in military applications.

6. Precision spot welding of electronic parts and close welding of relays.

7. In the electrical equipment industry, such as silicon steel plate welding, air-conditioning rotor drive welding and leakage protection welding.

Applicable materials:

There are many kinds of materials that can be welded: cold work alloy steel, hot work alloy steel, nickel tool steel, steel alloy, high-strength aluminum alloy, etc. Other metals such as gold, silver, brass, aluminum-magnesium alloy, titanium and platinum are also suitable.

Parameters

|

Module way |

4-axis linkage |

|

Work schedule |

200x200/300x300(optional) |

|

System language |

Chinese/English |

|

Electrical connections |

AC380V ± 5%, 50HZ / 60HZ |

|

Working environment |

Temperature≤40℃/Humidity< 90% |

|

Equipment size |

1500x750x1200 mm |

![]()

|

Unit type |

RL-Y200 |

RL-Y300 |

RL-Y400 |

|

Laser wavelength |

1064nm |

||

|

Laser power |

200W |

300W |

400W |

|

Beam diameter |

2.0 mm |

||

|

Adjustable light spot |

±3.0mm |

||

|

Pulse width |

0.1-15ms |

||

|

Repetition frequency |

1.0~40.0Hz |

||

|

A single point of energy |

60J |

70J |

80J |

|

Overall power consumption |

3.5kW |

5kW |

6kW |

|

Cooling system |

Water cooling |

||

|

Monitoring system |

CCD Monitoring system |

||

|

Control Method |

CNC Control |

||

|

Pump light source |

Single lamp |

Double light |

Double light |

|

Module way |

4 axis linkage |

||

|

Work schedule |

|

200x200/300/x300(optional) |

|

|

Manipulation language |

Chinese/English |

||

|

Electrical connections |

AC220V ± 5%, 50HZ / 60HZ |

AC380V ± 5%, 50HZ / 60HZ |

AC380V ± 5%, 50HZ / 60HZ |

|

Work environment |

Temperature≤40℃/Humidity< 90% |

||

|

Net weight |

350kg |

500kg |

500kg |

|

Gross weight |

380kg |

540kg |

540kg |

|

Size |

1500x750x1200mm |

||

Samples

![]()

Packaging

Wooden case along with plastic film

![]()

FAQ

1. What are the main functions of the laser welding machine?

Mainly for the welding of metal to replace the traditional argon arc and soldering.

2. What are the advantages of laser welding?

Laser welding has no requirements for technicians, it is quick to get started, there is no heat deformation after welding, and it can be used without polishing and grinding.

3: How can I use the machine, if I'm a new buyer?

We will deliver English manual and video with the machine to you. If you still need our help, please contact us.

4: How can I know your machine is designed for my product?

You can send us samples and we test it on the machine.