-

Metal Fiber Laser Cutting Machine

-

Industrial Laser Cutting Machine

-

Fiber Laser Tube Cutting Machine

-

Laser Cleaning Machine

-

Handheld Laser Welding Machine

-

Fiber Laser Marking Machine

-

UV Laser Marking Machine

-

Laser Welding Machine

-

Precision Fiber Laser Cutting Machine

-

Jewelry Laser Welding Machine

-

3D Metal Printing Machine

-

Laser Fume Extraction Systems

-

Fiber Laser Source

-

Laser Machine Parts

-

CO2 Marking Machine

-

Laser Obstacle Remover

-

Gold Testing Machine

-

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine!

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine! -

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service.

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service. -

StefanoThe machine looks sturdy...well built.. like it!

StefanoThe machine looks sturdy...well built.. like it!

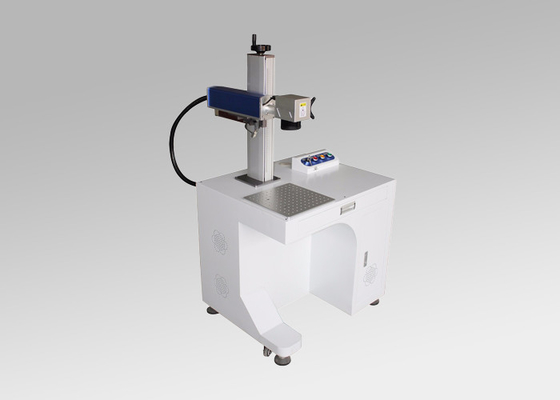

Table Type Fiber Laser Marking Machine for Gold Silver Jewlery

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Fiber Laser Marking Machine | Power | 20w /30w |

|---|---|---|---|

| Working Area | 110*110mm | Marking Speed | <7000mm/s |

| Power Supply | AC220V/50HZ | Package | Wooden Case |

| Warranty | 2 Years | ||

| Highlight | fiber laser engraving machine,laser marking equipment |

||

Table Type Fiber Laser Marking Machine for Gold Silver Jewlery

-Why choose fiber laser marking machine?

Permanent marks of all kinds are required on many products today. Fiber lasers, because of their extremely long operational life, lack of required maintenance or alignment and relatively low cost are rapidly becoming the marking method of choice for industrial marking applications. As government regulations become more strict about disposal of traditional marking materials like ink and acid etching chemicals, companies are looking for ways to make their product marking easier and environmentally friendly.

![]()

-What is the Advantages of Fiber Laser Marking machine?

It does not affect the integrity of the part;

Produce a high-contrast permanent mark;

Requires almost no maintenance;

Can be operated from almost any Windows-based software;

Is exceptionally easy to use by practically anyone in your organization!

Main Features:

1.Excellent beam quality:Compared with the traditional solid laser marking machine, machine output, gathering spot diameter less than 20um. divergence angle is semiconductor-pumped laser one-fourth. especially suitable for precise, refined marking.

2.Very long working life, 100000 working hours and no need maintainance

3.Very very thinner lines than traditional solid laser marking systerms.

4.Wide application, could work on NON-METAL and METAL material.

5.High converstion efficiency of electro-optic, the power consumption of the whole equipment is below 600W, it is only 1/10 of the solid laser marking machine pumped by the lamp.

Technical Parameters:

| 20W Fiber Laser Marking Machine | ||

| Maxphotonics Fiber Laser Source | Laser Wavelength | 1064mm |

| Average Output Power | 20W | |

| Pulse width | 80~90ns | |

| Modulation Frequency Range | 30~60KHZ | |

| Scanner Head | Maximum Speed | ≤7000mm/s |

| Resolution | 0.01mm | |

| Repeat Accuracy | 0.03mm | |

| Marking Software | EZ CAD Control Card + Software | |

| System Properties | Marking Range | 110*110mm |

| Minimal character | 0.01mm | |

| Minimum Character Height | 0.3mm | |

| Cooling ways | Force-air Cooling | |

| Power supply | 0.5KW/AC220V/50HZ | |

| Working Temperature | 0-40℃ | |

1. According to the marking area:

20w :100mmx100mm,175mmx175mm

30w:100mmx100mm,175mmx175mm,200mmx200mm

50w:100mmx100mm,175mmx175mm,200mmx200mm,250mmx250mm,300mmx300mm

2.According to the depth requet:

20w :0.2mm (depend on the materials)

30w:0.3mm(depend on the materials)

50w:0.5mm(depend on the materials)

Please noted that laser marking machine is not good at marking depth , if you want to get the effect depth you want , it will be need marking many times.

-What is Marking description for some material ?

-Aluminum

Aluminum is one of the most commonly marked substrates and is used in many industries. Typically, with lighter marking intensity, aluminum will turn white. It looks good when the aluminum is anodized, but white marking is not ideal for bare and cast aluminum. More intense laser settings provide a dark grey or charcoal color.

![]()

-Stainless steel

Next to aluminum, stainless steel is the most commonly marked substrate we see at Kuntai Laser. It is used in virtually every industry. There are several types of steels, each with varying carbon content, hardness, and finishes. Part geometry and size also vary greatly, but all allow for a variety of marking techniques.

![]()

-Plastics and Polymers

Plastics and polymers are by far the most expansive and variable materials that are marked with lasers. There are so many different chemical compositions that you cannot categorize them easily. Some generalizations can be made in terms of markings and how they will appear, but there is always an exception. We recommend test marking to ensure the best results. A good example of material variability is delrin (AKA Acetal). Black delrin is easy to mark, providing stark white contrast against the black plastic. Black delrin is truly an ideal plastic for showcasing the capabilities of a laser marking system. However, natual delrin is white and does not mark at all with any laser. Even the most powerful laser marking system will not make a mark on this material.

The most common technique in plastic and polymer marking is color changing. This type of mark uses the energy of the laser beam to alter the molecular structure of the piece, resulting in a change in the color of the substrate without damaging the surface. Some plastics and polymers can be lightly etched or engraved, but consistency is always a concern.

![]()

-Coated and Painted Metal

There are many types of coatings used to harden or protect metals from corrosive elements. Some coatings, such as powder coat, are thicker and require more intense laser settings to completely remove. Other coatings, like black oxide, are thin and meant to protect only the surface. These are much easier to ablate and will provide great contrast marking.

Each and every Kuntai Laser series is capable of marking on coated and painted metals and the ideal system for your application depends on your marking requirements. It may not be ideal for removing a powder coat but it can easily mark a powder coat. Our more powerful fiber lasers come in 20-50 watts, and can easily remove the powder coat and mark the underlying surface. Our fiber lasers can ablate, etch and engrave coated metals.

![]()

-Brass and Copper

Brass and copper have high thermal conductivity and thermal transfer properties and are used commonly for wiring, printed circuit boards and pressurized flow meters. Their thermal properties are ideal for laser marking systems for metal because the heat is quickly dissipated. This reduces the impact the laser can have on the structural integrity of the material.

Each and every Kuntai Laser series is capable of marking on brass and copper and the ideal system for your application depends on your marking requirements. The best marking technique depends on the finish of the brass or copper. Smooth surfaces can offer a soft polished marking affect, but they can also be annealed, etched, or engraved. Granular surface finishes offer little opportunity for polish. Etching or engraving is best in order to provide readability by humans and machines. In some cases a dark anneal can work, but surface irregularities can cause reduced readability.

![]()

-Silver and gold

Precious metals like silver and gold are very soft. Silver is a tricky material to mark as it oxidizes and tarnishes easily. Gold can be very easy to mark, requiring little power to get a good, contrasting anneal.

Each and every Kuntai Laser series is capable of marking on silver and gold and the ideal system for your application depends on your marking requirements. Because of the value of these substrates, engraving and etching are not common. Annealing allows the surface oxidation to create contrast, removing only a negligible amount of material.

![]()