-

Metal Fiber Laser Cutting Machine

-

Industrial Laser Cutting Machine

-

Fiber Laser Tube Cutting Machine

-

Laser Cleaning Machine

-

Handheld Laser Welding Machine

-

Fiber Laser Marking Machine

-

UV Laser Marking Machine

-

Laser Welding Machine

-

Precision Fiber Laser Cutting Machine

-

Jewelry Laser Welding Machine

-

3D Metal Printing Machine

-

Laser Fume Extraction Systems

-

Fiber Laser Source

-

Laser Machine Parts

-

CO2 Marking Machine

-

Laser Obstacle Remover

-

Gold Testing Machine

-

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine!

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine! -

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service.

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service. -

StefanoThe machine looks sturdy...well built.. like it!

StefanoThe machine looks sturdy...well built.. like it!

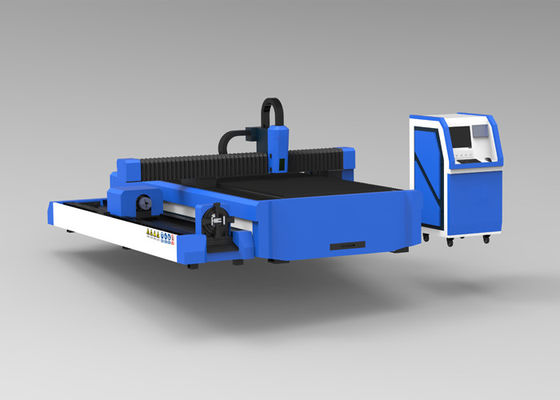

Middle Power 1500W Laser Cutting Machine with Servo Motor Drive for Stainless Steel

| Place of Origin | Shenzhen, China |

|---|---|

| Brand Name | Rise Laser |

| Certification | CE / FDA |

| Model Number | RL-3015-1500 |

| Minimum Order Quantity | 1 SET |

| Price | USD Negotiable |

| Packaging Details | Wooden box with iron binding belt |

| Delivery Time | 15 - 30 Work Days |

| Payment Terms | T/T, L/C, Western Union |

| Supply Ability | 2000 Units per year |

| Cutting Area | 1500*3000mm | Cooling Mode | Water Cooling |

|---|---|---|---|

| Laser Power | 1500W | Control Software | Cypcut |

| Condition | New | Worktable Max Load | 1000kgs |

| CNC Or Not | Yes | Laser Wavelength | 1060-1080nm |

| Positioning Accuracy | ±0.05 Mm | Working Voltage | 380V/50Hz |

| Highlight | stainless steel laser cutting machine,fiber laser metal cutting machine |

||

1500W Middle Power Metal Fiber Laser Cutter for Thick Stainless Steel Cutting

Product Description:

1. The machine is welded with a high-intensity whole sheet, and after high temperature annealing,the machine can be used for 20 years without any deformation.

2. With imported precision gear and rack, linear guide rail and transmission,the machine tool is of high precision, high efficiency and high stability.

3. Equipped with advanced wireless handheld terminal,the machine can be operated with remote control.

4. The equipment adopts the laser special speed matching system, high performance servo motor drive, is the integration of pneumatic, mechanical, photoelectric, numerical control and other advanced technologies as one of the high-tech products.

Features:

1. Excellent overall performance, changeable working tables, 7 seconds to finish high speed changing, improve working efficiency of more than 48%.

2. The machine tool includes loading area and processing area, standard configuration is changeable working tables, auto change the workpiece between processing area and loading area by motor, convenient to upload and download. With the design of changeable working table, could prepare the next uploading while processing, highly improved working efficieny.

3. Equipped with exhaust device, have good exhausting effect and little pollution.

4. Small occupied area, high system integration, convenient to operate and maintenance, 24 hours continuous working.

5. The water chiller has good safety protection function, such as over temperature, lack phase, pressure, water-break, undervoltage, overload, etc. With stable performance, satisfied the cooling requirement of laser source.

Fiber Laser Cutting Machine Different Laser Sources Comparing:

| Model of Laser Source | Fiber | CO2 | Disc |

| Electro-optical Conversion Efficiency | 30% | 10% | 15% |

| Max. Output | 50Kw | 20Kw | 8Kw |

| BPP(4/5Kw) | <2.5 | 6 | 8 |

| Life of Diode Pumped | >100,000 | NA. | 10,000 |

| Occupied Area(4/5Kw) | <1M2 | 3M2 | >4M2 |

| Maintenance | no need | need | Often |

| Soft Processing | more suitable | unsuitable | suitable |

| Stability | best | good | good |

| Absorption rate%--steel | 35 | 12 | 35 |

| Absorption rate%--aluminum | 7 | 2 | 7 |

| Replaced Parts | High brightness semiconductor laser broadband single core, more than 100,000 hours of pump. Damage to one of the semiconductor does not affect the normal work of the laser, but less and less power, because each semiconductor pump sources are used to separate each other. | Laser work requires gas supplement, reflection lens replacement. | Semiconductor Bar (array) maximum pulse model 5000 hours or 10000 hours continuous mode. Laser use the pump sources are used in the process of often need to change, each time change need to be between $200,000-230,000. |

Applied materials of 1500W Fiber Laser Cutting Machine:

Fiber cutter is mainly used for carbon steel cutting, mild steel, stainless steel, silicon steel,aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials. It is an cnc laser cutters can be used to do high precision cutting. It also can be called fiber cutter machine,fiber optic laser cutter,laser cutter for metal,fiber cutter,carbon steel cutting,cnc laser cutters.

Technical Parameter:

| Working Area | 3000*1500mm |

| Controller+Heigh follower | Cypcut |

| Laser Source | Fiber Laser Source 1500W |

| Wave Length | 1070nm±10nm |

| Laser Head | Optional |

| Gear and Rack | Germany |

| Guide Rail | Taiwanese HIWIN |

| Positioning Precision | ≤±0.04mm |

| Cutting Thickness | 1-20mm |

| Max cutting speed | 40000mm/min(according to materials) |

| Working voltage | AC220V/110V±10% 50HZ/60HZ |

| Min line Width | ≤0.12mm |

| Transmission | Yaskawa servo 850W+FASTON reducer |

| Z axis | Yaskawa 400W+brake |

| Cooling | Water Cooling |

| Structure | 10mm Thickness Welded steel tube,Aluminium Alloy Gantry |

| Power Consumption | ≤7.5KW |

![]()

Performance for 1500W Fiber Laser Cutting Machine:

1.The machine enjoys outstanding performances with high cutting speed, high efficiency, safety and stability. And diode pump solid state laser has the advantage of longer working life, free maintenance and the highest photo-electric conversion efficiency. It also ensures a small divergence angle and light beams of good quality.

2. The light spot enjoys good quality and small heat deformation. Besides, cutting seams are even and nice.

3. After tempering treatment, steel frames with high rigidity are of high vibration-absorbed performance with tempering treatment. And frames with gantry structure are one-step processed in large CNC gantry machining center. With optimized structure, the machine enjoys stability and high accuracy.

4. Imported servo motors and sophisticated direction transmission mechanism ensure high steadiness and accuracy.

5. An intuitive human-machine interface (HMI) with many practical functions is easy to operate.

6. An imported ball screw and linear guides ensure transmission and direction.

7. The sealed cutting head automatically tracks work pieces and has the function of anti-collision.

8. The power supply of the machine is designed with automatic safety protection, and features fault alarm.

9. With fashionable, delicate and artistic design, the compact machine covers smaller floor area without scattered parts. And it’s easy to operate the machine.![]()

Applied Industry of 1500W Fiber Laser Cutting Machine:

This laser cutter for metal is applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.