CO2 laser cutting helps factories to manufacture items quickly and accurately. This method is especially good for cutting non-metallic materials, and acrylic sheets is one of the best materials to cut with this laser. The clear acrylic is strong and durable, and light can pass through it, making it ideal for a variety of uses. When cut with a CO2 laser, acrylic edges are smooth and require no additional cleanup.

Characteristics of Acrylic Sheets

Acrylic sheets are useful in many different industries. These sheets are clear like glass, but are stronger, can handle harsh weather without damage, and are easy to work with when they need to be cut or shaped. Other methods of cutting acrylic sheet often leave rough edges that require further processing. the CO2 laser solves this problem by providing a clean cut the first time.

How CO2 Laser Cutting Works

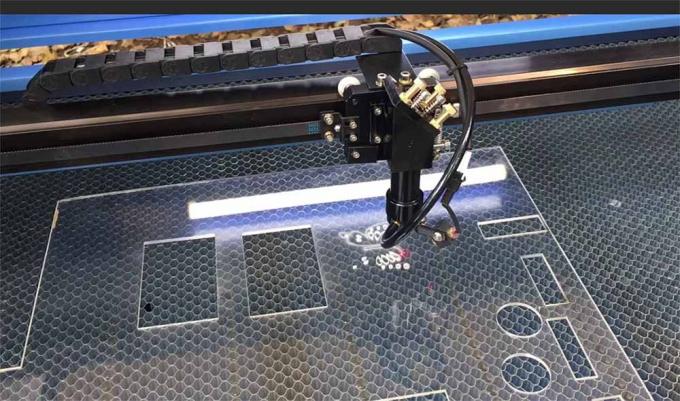

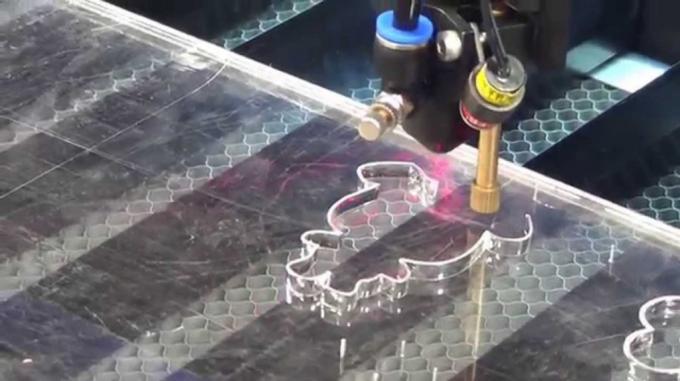

The machine focuses a powerful laser beam on a tiny spot on the material, making it so hot that it melts or turns to vapor. A special gas like nitrogen or regular air blows the melted material away from the cut. This process has many benefits that make it better than older cutting methods.

Laser cutting wastes very little material and works fast. The thin laser beam can make very precise cuts without heating up too much of the surrounding material. Complex shapes and patterns are easy to cut with this method, which makes it great for detailed work. When cutting acrylic sheets, two things matter most: how powerful the laser is and how fast it moves. Using a strong laser that moves quickly helps keep the acrylic from getting too hot and ensures the cuts come out smooth.

Optimizing Acrylic Sheet Processing

You need to plan carefully to get the best results when cutting acrylic sheets. Design your pieces so they fit together well, using edges that curve inward and outward to make stronger connections. Leave enough space between parts as you cut them – about a quarter to half the thickness of your acrylic sheet. When you’re cutting shapes like squares or triangles, try to share edges between pieces to save time and material.

Getting your laser settings right is very important. Use full power when you’re cutting thick acrylic sheets. For thinner sheets, turn the power down a bit so you don’t melt them too much. The cutting speed makes a big difference in how your pieces turn out. Going faster keeps the acrylic from getting too hot, but moving too quickly might give you rough edges.

Examples of Laser-Cut Acrylic Applications

Schools and colleges use laser cutting a lot. Students can quickly turn their ideas into real objects for projects and contests. A college team showed how well this works by making a test model with pieces that locked together perfectly. They kept improving their design until it worked just right. When they needed something stronger, they could copy the same design in metal.

Businesses use laser-cut acrylic for many things. They make store displays that catch people’s eye with clean, sharp edges. Signs, fancy wall panels, and special boxes all look better when they’re cut by laser. The cuts are so smooth and precise that the finished products look very professional.

Environmental Considerations

Laser cutting is good for the environment too. You can save the leftover pieces of acrylic and sort them by color and thickness for later use. Keep your acrylic sheets lying flat when you store them. This stops them from bending out of shape.

Here are some ways to waste less material. Use your small leftover pieces to make smaller things. Plan how you’ll arrange your cuts to use as much of the sheet as possible. When you store acrylic, keep it flat and level so it stays straight and usable for your next project.

Benefits of CO2 Laser Cutting for Acrylic Sheets

The way we cut acrylic with CO2 lasers keeps getting better. New machines can do more things, work faster, and make even better cuts than before. These improvements include better computer programs that help plan the cutting path, lasers that can make finer details, and machines that use less power to help the environment.

Cutting acrylic with CO2 lasers has many benefits. The process is much faster than old-style cutting methods, saving lots of time in the workshop. Laser cuts come out smooth and exact, so you don’t need to clean them up afterward. You can make all kinds of complex shapes and cut different thicknesses of acrylic, and because there’s less waste and faster cutting, you save money too.

Laser cutting works better than older methods in several ways. You don’t have to keep buying and replacing cutting tools like you do with regular machines. The cuts come out just as good whether you’re making something simple or complex. Workers can learn to use laser cutters more easily than traditional cutting machines.

Practical Tips for CO2 Laser Cutting

Here are some helpful tips for using CO2 laser cutters. Always test your settings on a scrap piece first to make sure everything’s working right. Watch out for too much heat building up – if the acrylic starts to melt, slow down or space your cuts further apart. Clean your machine’s lenses and check that everything lines up correctly to keep getting good results.

Conclusion

Let’s wrap up what we’ve learned about CO2 laser cutting. It’s a great way to cut acrylic sheets because it’s precise, fast, and can make all kinds of shapes. When you know how acrylic works, plan your cuts carefully, and use the right settings, you can make excellent products without wasting materials. As these machines get even better, more companies will use them to make things with acrylic. This technology will keep helping different industries come up with new and better ways to make products.