In the realm of thin plate welding, handheld laser welding machines are gaining widespread popularity owing to their swift performance, high efficiency, and impeccable weld quality. Selecting the right model is crucial to maximize these benefits. This article delves into the nuances of water-cooled and air-cooled handheld laser welding machines, shedding light on their differences in welding thickness capabilities.

Water-cooled vs. Air-cooled: A Structural Contrast

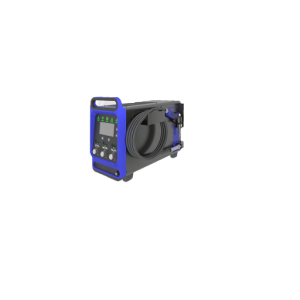

The nomenclature of water-cooled and air-cooled handheld laser welding machines stems from their distinct cooling methods, evident in their appearance and structure. Notably, the absence of a water tank renders air-cooled variants significantly smaller and lighter, weighing around 30 kilograms and boasting a volume half that of their water-cooled counterparts. This translates to enhanced mobility and convenience for air-cooled handheld laser welding machines.

Power Disparity and Material Welding Thickness

While the reduced size of air-cooled handheld laser welding machines enhances portability, it often comes at the expense of power. Generally, these machines exhibit lower power ratings compared to water-cooled counterparts. This power disparity manifests in limitations on material welding thickness. For instance, in the welding of 3mm thick stainless steel, a 1500W water-cooled handheld laser welding machine excels, whereas air-cooled options typically offer lower power variants like 800W and 1200W. Consequently, the welding effect on 3mm thick stainless steel may not match the capabilities of the more powerful water-cooled alternative.

Optimizing for Laser Welding Requirements

In practical terms, the choice between air-cooled and water-cooled handheld laser welding machines hinges on the specific welding needs. While air-cooled options may fall short for thicker materials, they excel in handling thin plates below 2mm. Therefore, assessing the desired welding thickness is paramount when optimizing your selection for a handheld laser welding machine.

Conclusion:

In navigating the diverse landscape of handheld laser machines, the decision between air-cooled and water-cooled variants is pivotal. While the former offers unparalleled mobility and convenience, the latter shines in higher power applications, catering to thicker materials. Understanding these differences allows you to make an informed choice, aligning the selected model with your specific welding requirements.

If you are interested in our products, please feel free to leave a message or contact us for a quotation.