-

Metal Fiber Laser Cutting Machine

-

Industrial Laser Cutting Machine

-

Fiber Laser Tube Cutting Machine

-

Laser Cleaning Machine

-

Handheld Laser Welding Machine

-

Fiber Laser Marking Machine

-

UV Laser Marking Machine

-

Laser Welding Machine

-

Precision Fiber Laser Cutting Machine

-

Jewelry Laser Welding Machine

-

3D Metal Printing Machine

-

Laser Fume Extraction Systems

-

Fiber Laser Source

-

Laser Machine Parts

-

CO2 Marking Machine

-

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine!

GustavoThanks for packaging.Your packages are well designed and prepared carefully. Looks fine! -

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service.

VictorThank you, Zoe. I just let you know I was quoting around 5 people about laser source. There were cheaper offers but I choose you in the end. I like your company especially the service. -

StefanoThe machine looks sturdy...well built.. like it!

StefanoThe machine looks sturdy...well built.. like it!

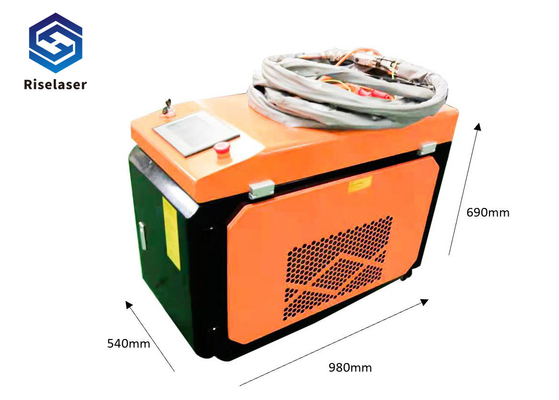

1000w Laser Rust Removal Machine CW For Cleaning Rusty Metal Car Shipbuilding Industry

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Laser Type | Laser Cleaning Machine 1000w | Laser Power | 1000W/1500W/2000W |

|---|---|---|---|

| Cooling Method | Water Cooling | Function | Cleaning Machine For Rust Paint Oil Dust |

| Fiber Cable Length | 3-5 M | Operation | Manual/auto |

| Laser Source | Raycus IPG MAX | Control Method | Control Panel |

| High Light | Laser Metal Rust Remover 1000w,Water Cooling Metal Laser Cleaning Machine |

||

Laser cleaning machine 1000w Laser Rust Removal Machine for cleaning rusty metal

Laser Cleaning Machine Introduction:

Laser cleaning equipment is a new generation of subsurface cleaning of high-tech products.

- Easy to install, control and automate.

- Easy to operate,turn on the power,open the device,you can carry no chemical reagents,no media,clean,anhydrous cleaning,can manually adjust te focus,fit subsurface cleaning,cleaning the subsurface cleanliness advantages,to clear the subsurface resin,oil,stains,dirt,rust,coating,paint.

Cleaning samples

![]()

![]()

![]()

Machine parameters

| Model | RL-C1000 | RL-C1500 | RL-C2000 |

| Wavelength | 1080nm | 1080nm | 1080nm |

| Average power | 1000W | 1500W | 2000W |

| Frequency | 20-50 kHz | 50 kHz | 50 kHz |

| Laser type | CW fiber laser | CW fiber laser | CW fiber laser |

| Clean speed | ≤40 M²/Hour | ≤40 M²/Hour | ≤40 M²/Hour |

| Fiber cable length | 10M(others for optional) | 10M(others for optional) | 10M(others for optional) |

| Working life | 100,000 hours | 100,000 hours | 100,000 hours |

| Machine weight | 120kg | 120kg | 120kg |

| Cooling | Water chiller cooling | Water chiller cooling | Water chiller cooling |

| Optional | Manual/Auto | Manual/Auto | Manual/Auto |

| Temperature | 5-40℃ | 5-40℃ | 5-40℃ |

| Beam width | 10-70mm | 10-70mm | 10-70mm |

| Clean speed | Single Phase 220V,50/60HZ |

Single Phase 220V,50/60HZ |

Single Phase 220V,50/60HZ |

Machine dimension

![]()

![]()

![]()

Applications of laser rust removal gun

Laser rust removal 1000w is widely used for the surface laser degreasing, laser paint removal, laser removal of zinc, laser film removal, laser cleaning, such as coating, etc

Machine brief introduction of laser rust removal gun

The laser cleaning Machine is a new generation of industrial surface cleaning laser system. It adopts the advanced laser source, laser optical scanners and control system to meet the requirements of metal surface cleaning process.

Laser dry cleaning method of laser rust removal gun

Use pulses laser to clean rust directly, it will generate vibration after the laser energy is absorbed by the base or particles, then seperate the base and comtaminant.